Reformer Tubes

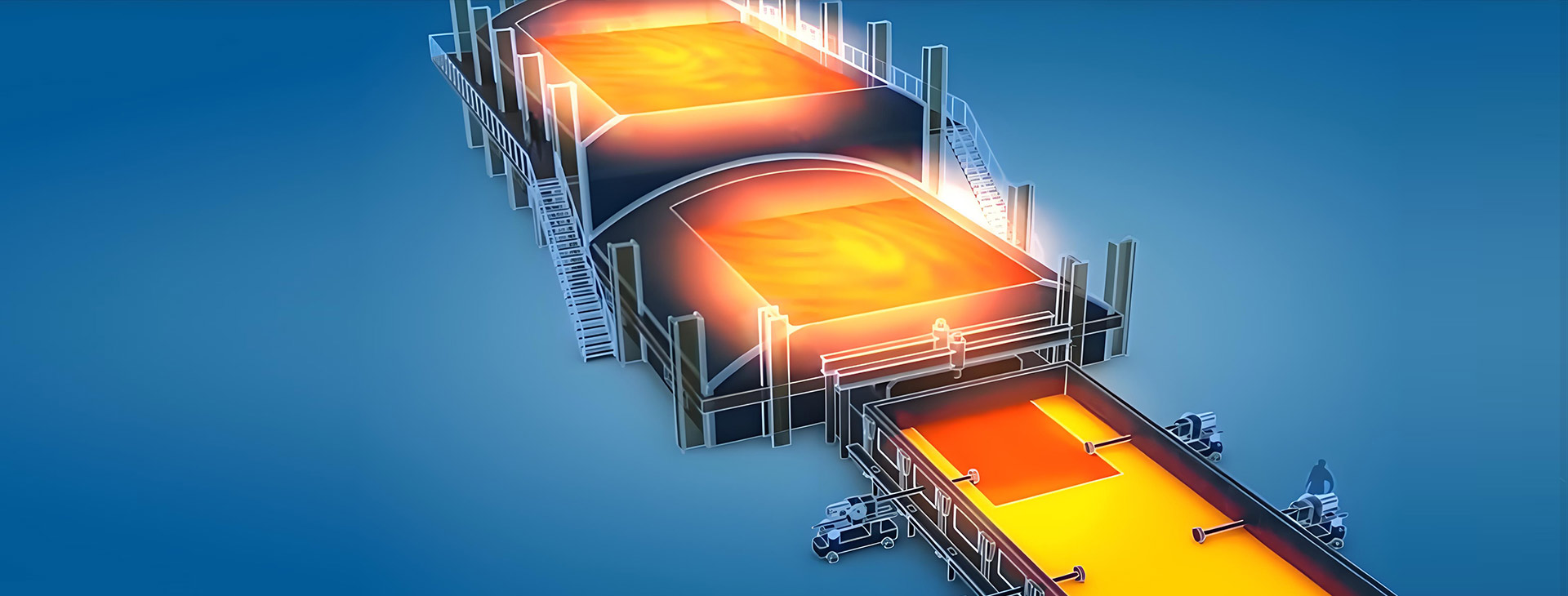

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Tube bevels

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Inlet manifold of reformer furnace

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Reducers

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Reformer tubes

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Transition piece form radiant outlet manifolds of reformer furnace

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Inlet manifold of reformer furnace

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Long tubes

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Manifold

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Long tubes

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Long tubes

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Reduers

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Reformer Tubes

Reducer assemblies

Reforming furnace tubes are predominantly employed in hydrogen reforming furnaces within oil refineries. These tubes utilize light hydrocarbons such as natural gas, refinery gas, and naphtha as primary feedstocks for hydrogen production. Additionally, they play a critical role in processes like synthetic ammonia production for fertilizers and methanol manufacturing, supplying the essential hydrogen feedstock for ammonia synthesis. Serving as the reactor, reformer tubes demand materials with exceptional high-temperature resistance and corrosion resistance, operating under pressure at temperatures up to approximately 1000°C.

Yantai Refra Heat Resistant Alloys Co., Ltd, has supplied numerous qualified reformer tube systems and related components to domestic and international clients. The products cover various furnace designs such as Topsoe, Technip, Foster Wheeler (FW), Linde, Kellogg, and Dehydrogenation Process Tube(DPT).

Operating temperature: ≤1100℃

Material properties: High-temperature resistance (≥1000℃), corrosion resistance, oxidation resistance and creep-resistance.

Representative materials: RF 35M, RF 35M-R

Designed lifetime:100,000 hours.

Application solution

Ethylene

Petrochemical

Steel

Float glass industries

中文

中文 English

English