Cracking furnace tubes

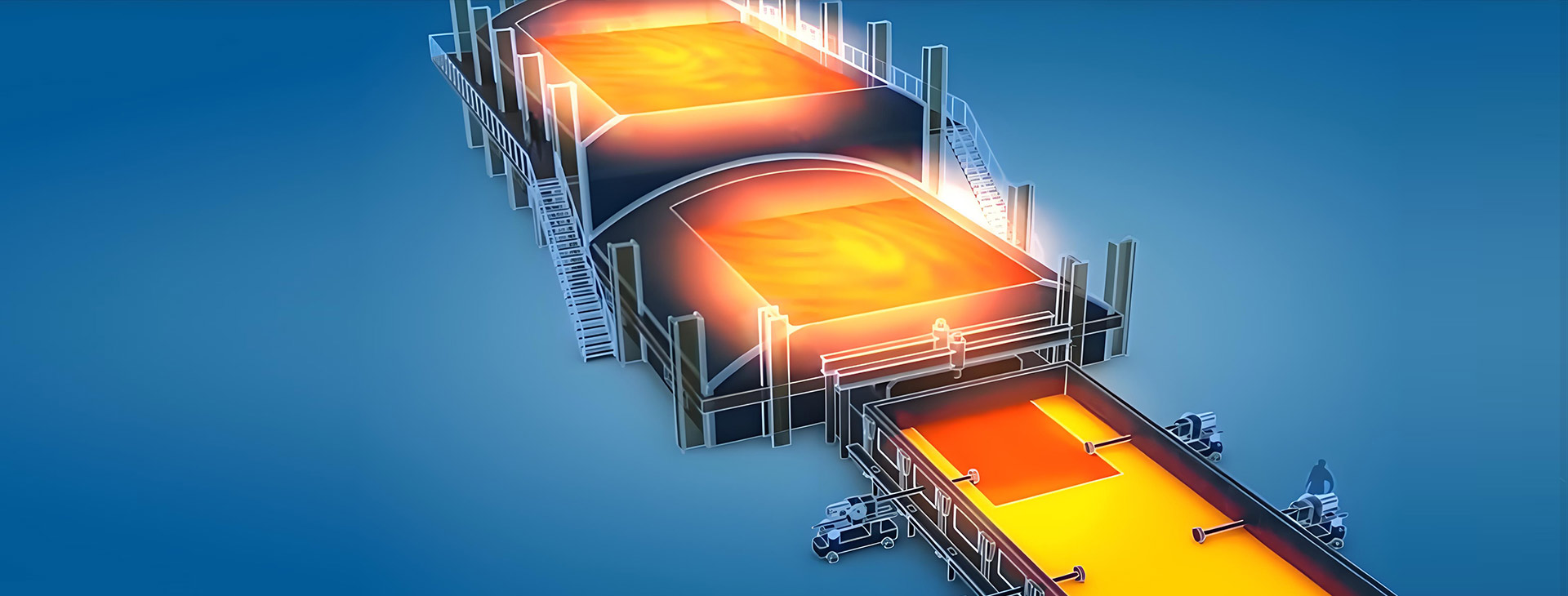

Radiant coils of cracking furnace

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

U-tubes

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

US-tubes

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Radiant coils of cracking furnace

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Inlet assembly of radiant tubes coils

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Radiant coils of cracking furnace

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Radiant coils of cracking furnace

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

4-in-1 Fitting

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Serpentine furnace tubes assembly

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

90 ° elbows with lugs

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Cracking furnace tubes

Y-shaped assemblies

In the steam cracking furnaces of the petrochemical industry, cracking furnace tubes and bend castings are required to withstand external temperatures approaching 1100°C, while simultaneously resisting internal carburization corrosion caused by hydrocarbon gases and external high-temperature oxidation. Consequently, the materials used must demonstrate exceptional corrosion resistance and creep resistance under these extreme high-temperature operating conditions.

Yantai Refra Heat Resistant Alloys Co., Ltd, relying on years of accumulated production experience and advanced manufacturing techniques, has provided various types of cracking furnace tubes and products, including long tubes, coils and key castings, to over a hundred domestic and international enterprises. The company's products fully cover the mainstream global ethylene cracking furnace technology routes, including typical furnace types developed by Lummus, Stone & Webster (SW), Technip FMC, Linde, Sinopec Engineering (SEI) and etc.

Operating Temperature Range: 800–1100°C (maximum up to 1200°C)

Pressure Conditions: Internal pressure, relatively low

Material Properties: High-temperature resistance (≥1000°C), corrosion resistance, oxidation resistance, and anti-coking

Representative materials: RF 35M, RF 45M, RF 45A

Application solution

Ethylene

Petrochemical

Steel

Float glass industries

中文

中文 English

English